• Established in 2020

• 5000 Square meters large

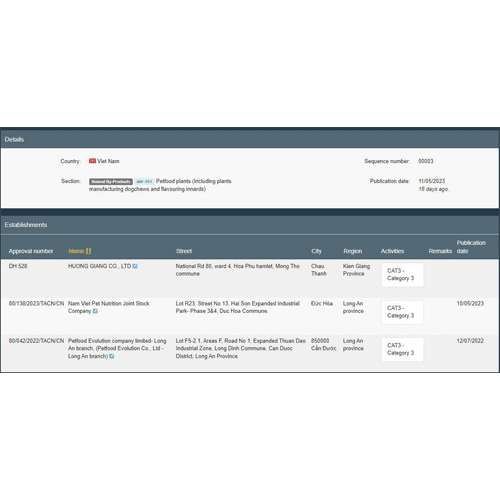

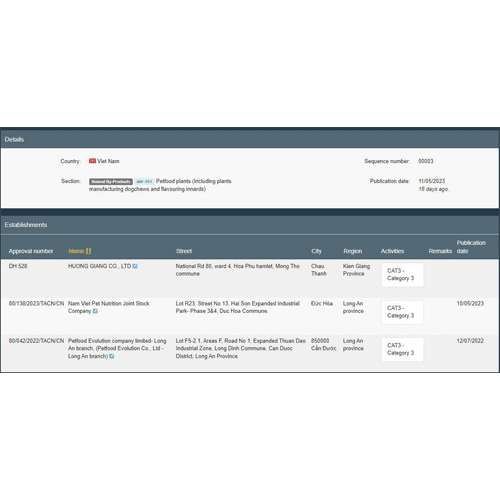

• Located in Long An province, Vietnam.

• A manufacturer of dried pet chews for domestic market and export markets.

• Designed to produce 15 containers monthly

of dog chews and treats.

At NaviPet, we are committed to producing top-quality pet food, serving our customers. Every product we offer is designed not only to nourish pets physically but also to contribute to their long-term happiness and health. We pride ourselves on being a reliable partner, with stringent production processes, environmentally friendly raw materials, and a dedication to sustainable development. Our goal is to provide exceptional value to our customers and partners.

Contact With Us

Become the top symbol of customer trust. It's a product that ensures the health and nutrition of pets.

Get In TouchNaviPet has 3 production lines

• Plant-based products

• Animal products

• Products from seafood

NaviPet has lines and equipment suitable for the production of pets chews.

Building a production system that meets international standards BRC

Become a reputable supplier of mixed pet chews for domestic, Japanese and European markets

Building a production system that meets international standards HACCP

Being the first pet chews company to meet export standards to the European market

Chemical test

• Environment/ Water

• Quality

• Pesticide Residue

• Bestial Medicine Residue

• Aflatoxin

• Mould

• Melamine

Physical test

• Crude Fat

• Crude fiber

• Crude Ash

• Moisture

• Package Test

Microbiology

• E. Coli

• Coliform

• Total Plate count

• Salmonella